Material application

Our depth of experience has allowed us to work with the full range of commodity and engineering thermoplastics in simple products to applications demanding performance in extreme environments. Many of the world’s leading commodity plastic resin manufacturers are located in Dongguang. We are strategically located close to these manufacturers providing access to material, plastic engineering resources, and a vast network of plastic engineering and testing facilities supporting the development of polyethylene and polypropylene polymers. We also collaborate regularly with the world’s leading engineering resin manufacturers and plastic compounders on plastic material development for specific product applications.

These partnerships provide additional support from polymer engineering laboratories and the plastic resin material development experience that we offer to our customers.

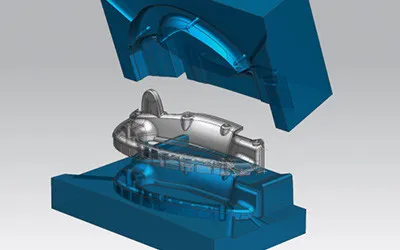

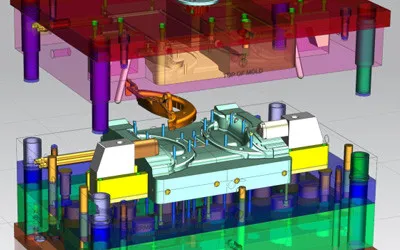

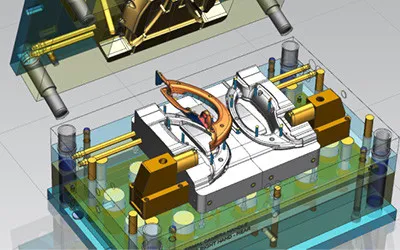

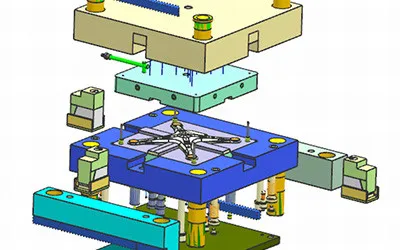

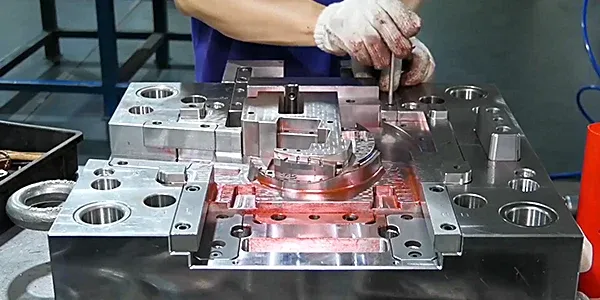

Plastic fasteners & Plastic fasteners Tool Design

Plastic fastener tooling includes shaping and producing the metal components of a mold that will give a product its final shape. Tooling requires careful planning so that each casting cavity and a core box of a mold is perfectly designed to manufacture products that will meet the required specifications.

OFasteners Mold

As a custom manufacturer of plastic fasteners, we manage the tool design and build of low-volume simple geometry injection molded parts to fully automated, high-volume injection molded parts with complex geometry and aggressive materials. We build to the Society of Plastic Industry, SPI, and fasteners building standards. Where appropriate in lower-volume applications our engineers will utilize family tools with hand-load inserts for undercuts and threaded components. Slides and automated unscrewing devices use the hydraulic core pull feature on the injection molding machine which is cost-effective to produce undercuts and threaded parts.

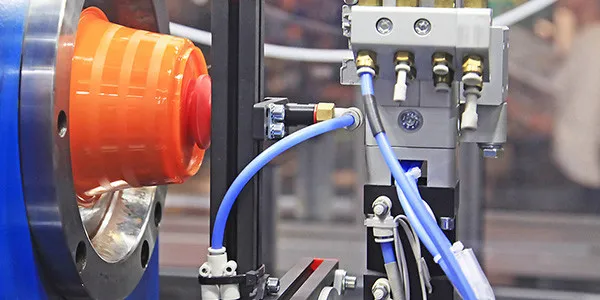

Fasteners Molding

OFasteners is your premiere provider of plastic fasteners and CNC process services. We have years of experience in serving industries such as spaceflight, food and beverage, energy, electronics and business equipment, and many others. We understand the need to be precise in fastener tool design and maintenance. We remain flexible and knowledgeable in any situation that may arise during the manufacturing process. We are here to guide you in the right direction. The heart of everything we do revolves around the plastic fastener process. Our engineering and management all have led and managed fasteners molding tooling shops. We deliver the experience of in-house tool design/build and a network of N. American and global relationships of “world-class” partners to deliver cost-effective molds all built to the Society of Plastic Industry fasteners building standards.